Top 10 Robotics Trends to Watch in 2026

Robotics is moving from experimentation to core infrastructure in enterprise operations. This analysis examines ten trends shaping adoption in 2026, including AI-native control, digital twins, edge computing, and safety governance, with insights from vendors and analysts.

Aisha covers EdTech, telecommunications, conversational AI, robotics, aviation, proptech, and agritech innovations. Experienced technology correspondent focused on emerging tech applications.

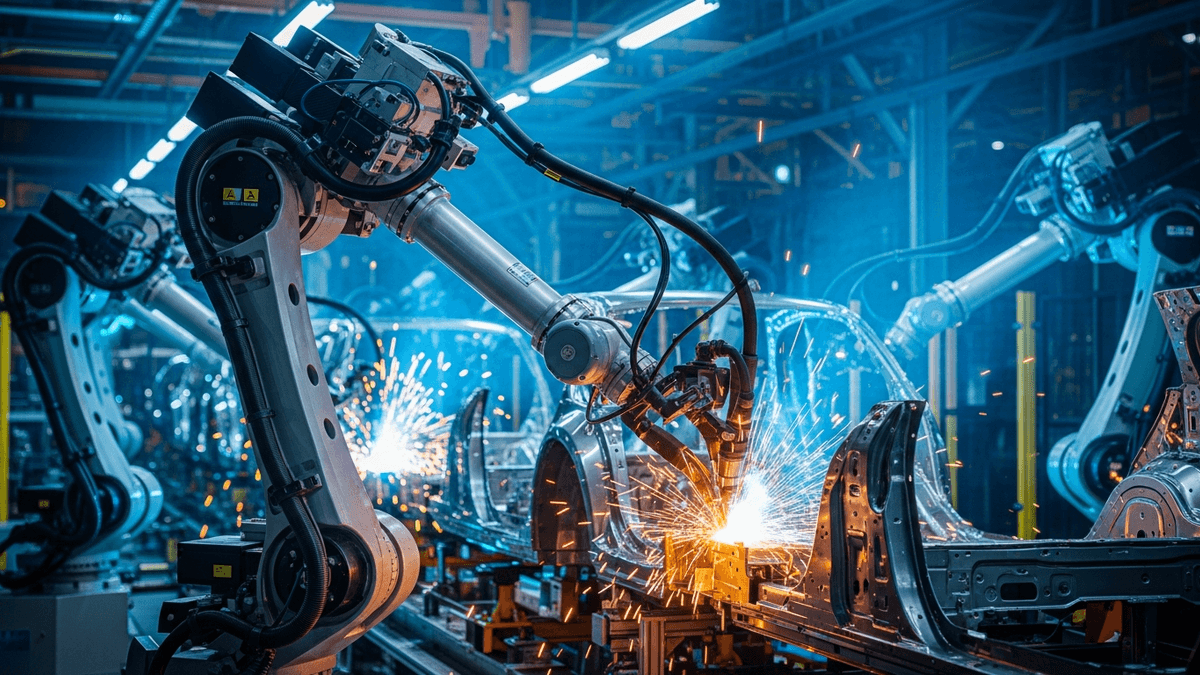

LONDON — January 27, 2026 — Enterprises across manufacturing, logistics, retail, healthcare, and energy are elevating robotics from pilot projects to mission-critical infrastructure as vendors refine platforms and standards improve interoperability.

Executive Summary

- Robotics strategies increasingly integrate AI-native control, simulation, and edge computing to achieve reliability in production settings, per January 2026 industry briefings (Gartner insights).

- Safety, cybersecurity, and data governance have become core design requirements for large-scale deployments, supported by evolving standards from ISO and IEEE.

- Vendor ecosystems—spanning Nvidia, Amazon Web Services, Microsoft Azure, Google Cloud, and integrators—are consolidating capabilities around simulation, orchestration, and MLOps.

- Collaborative robots (cobots), autonomous mobile robots (AMRs), and human-assist systems are gaining traction in high-throughput environments where precision and safety are paramount (McKinsey operations research).

Key Takeaways

- Focus deployments on AI-centric stacks that unify perception, planning, and control; prioritize simulation and digital twins for validation (Nvidia Isaac).

- Operationalize governance with safety certifications, threat models, and audit trails across fleets and sites (NIST Cybersecurity Framework).

- Drive ROI with modular cobots and AMRs integrated into MES/WMS/ERP systems; benchmark time-to-value against legacy automation (Siemens Digital Industries).

- Build for interoperability via ROS, open APIs, and standardized data schemas to avoid vendor lock-in (ROS).

| Trend | Enterprise Impact | Adoption Stage | Representative Vendors |

|---|---|---|---|

| AI-Native Control | Improves precision and adaptability in variable environments | Scaling in production | Nvidia, AWS, Google Cloud |

| Digital Twins & Simulation | De-risks deployment and accelerates validation cycles | Widely piloted | Siemens, PTC ThingWorx, Microsoft |

| Edge Computing | Lower latency for safety-critical control | Core requirement | Intel, Arm, Qualcomm |

| Cobots & AMRs | Flexible automation for high-mix operations | Strong momentum | Universal Robots, ABB, Boston Dynamics |

| Fleet Orchestration | Centralized monitoring, updates, and scheduling | Standardizing | Amazon Robotics, GreyOrange, 6 River Systems |

| Safety & Governance | Compliance and auditability at scale | Becoming mandatory | ISO, IEEE, NIST |

| Interoperability & ROS | Avoids lock-in; accelerates integration | Baseline expectation | Open Robotics, Open Robotics Foundation, ROS 2 |

| AI Safety & Cybersecurity | Protects fleets, data, and human workers | Embedded in design | Palo Alto Networks, CrowdStrike, Microsoft Security |

Competitive Landscape

| Company | Primary Focus | Core Capabilities | Reference Link |

|---|---|---|---|

| Nvidia | Robotics AI & Simulation | Perception, planning, digital twins | Isaac platform |

| AWS | Cloud Robotics Services | Simulation, fleet services, integration | AWS RoboMaker |

| Microsoft Azure | Edge + Cloud Orchestration | DevOps, security, digital twins | Azure Digital Twins |

| Google Cloud | AI Services & Tooling | ML pipelines, data ops, orchestration | Robotics solutions |

| ABB Robotics | Cobots & Industrial Robots | Safety, integration, lifecycle | ABB Robotics |

| Universal Robots | Cobots | Rapid deployment, modularity | UR cobots |

| Boston Dynamics | AMRs & Mobile Platforms | Mobility, autonomy, perception | Company site |

| Siemens | Digital Twins & Automation | Simulation, MES integration | Siemens automation |

Disclosure: BUSINESS 2.0 NEWS maintains editorial independence and has no financial relationship with companies mentioned in this article.

Sources include company disclosures, regulatory filings, analyst reports, and industry briefings.

Related Coverage

About the Author

Aisha Mohammed

Technology & Telecom Correspondent

Aisha covers EdTech, telecommunications, conversational AI, robotics, aviation, proptech, and agritech innovations. Experienced technology correspondent focused on emerging tech applications.

Frequently Asked Questions

Which robotics trends are most impactful for enterprise operations in 2026?

Enterprises are prioritizing AI-native control stacks, digital twins for validation, edge computing for low-latency safety, and fleet orchestration to manage multi-site deployments. Cobots and AMRs are being deployed for high-throughput tasks such as kitting, inspection, and goods-to-person workflows. Vendors including Nvidia, AWS, Microsoft Azure, Google Cloud, ABB, Universal Robots, and Boston Dynamics offer platforms and hardware that support these requirements, while standards bodies like ISO and IEEE codify safety and interoperability expectations.

How should organizations architect robotics systems for reliability and scale?

Design around modular components: perception, planning, and control tied to simulation and digital twins for lifecycle validation. Combine edge accelerators with cloud orchestration, implement OTA updates, and enforce role-based access. Align with security frameworks like NIST and certifications such as SOC 2 and ISO 27001. Integrate robotics telemetry and commands into MES/WMS/ERP using open APIs and ROS to avoid lock-in, and build observability for monitoring, incident workflows, and audit trails.

What best practices improve ROI when moving from pilot to production?

Focus on well-scoped, repeatable workflows; set clear KPIs for throughput, quality, and safety; and phase rollouts to manage change effectively. Use simulation to de-risk model and control updates and leverage fleet orchestration for centralized monitoring, scheduling, and policy enforcement. Partner with integrators experienced in warehouse and manufacturing integrations, and align with standards from ISO, IEEE, and NIST to streamline compliance while reducing operational risk.

Which vendors and tools support interoperability and standards-based deployment?

Open-source stacks like ROS and ROS 2, combined with vendor SDKs, underpin cross-platform integration. Cloud vendors (AWS, Microsoft Azure, Google Cloud) provide robotics services and digital twin tooling, while industrial platforms from Siemens and PTC connect robotics to MES and PLM. Hardware providers such as ABB, Universal Robots, and Boston Dynamics ensure safety and reliability, and cybersecurity tools from Microsoft Security, Palo Alto Networks, and CrowdStrike protect fleets and data.

What governance and security measures should be embedded in robotics programs?

Adopt a layered approach: enforce identity and access controls, encrypt telemetry, and maintain secure OTA pipelines for models and firmware. Align with NIST guidance and pursue SOC 2 and ISO 27001 where appropriate, ensuring GDPR compliance for sensitive data. Implement continuous risk assessment for human-robot collaboration, formal incident response workflows, and audit trails. Standardize policies across fleets and sites to guarantee consistent safety and ethical operation at scale.