How Industrial AI Robots Are Transforming Manufacturing Efficiency

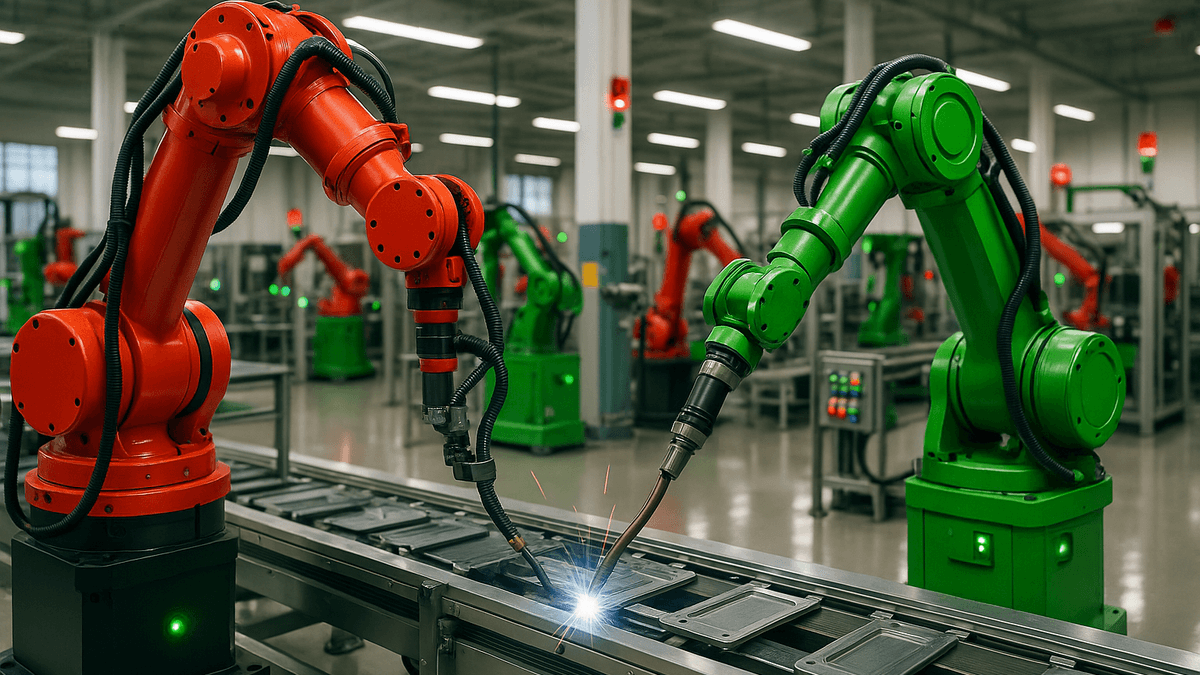

Industrial robots are moving from isolated cells to connected, AI-enabled systems that lift throughput, quality, and resilience across factories. This analysis explains the technology stack, the vendor landscape, and best practices for deploying robots at scale—grounded in data, standards, and real-world architectures.

Dr. Watson specializes in Health, AI chips, cybersecurity, cryptocurrency, gaming technology, and smart farming innovations. Technical expert in emerging tech sectors.

- Operational stock of industrial robots exceeds 3.9 million worldwide, with annual installations surpassing half a million units, according to the International Federation of Robotics (IFR), underscoring mainstream adoption in manufacturing (IFR World Robotics).

- Automation can add 0.8–1.4 percentage points to global productivity growth annually, with industrial robotics a core lever for throughput, quality, and cost efficiency (McKinsey Global Institute analysis).

- Global leaders such as ABB, FANUC, KUKA, Yaskawa, and Universal Robots anchor the hardware market, while platforms from Siemens, Rockwell Automation, and Nvidia connect robots to digital twins, industrial control, and AI (Nvidia–Siemens collaboration overview).

- Best-in-class deployments combine standardized cells, offline programming, machine vision, and safety-by-design aligned to ISO 10218/TS 15066 and ISA/IEC 62443, enabling scale with measurable ROI (ISO 10218; ISO/TS 15066; ISA/IEC 62443).

| Vendor | Headquarters | Specialty | Source |

|---|---|---|---|

| ABB | Zurich, Switzerland | Articulated robots, digital twin, offline programming (RobotStudio) | ABB Robotics portfolio |

| FANUC | Oshino, Japan (FANUC Corp.) | High-speed articulated/SCARA, reliability at scale | FANUC industrial robots |

| KUKA | Augsburg, Germany | Flexible manufacturing cells, human-robot collaboration | KUKA industrial robots |

| Yaskawa | Kitakyushu, Japan | Motion control, welding and handling robots (MOTOMAN) | Yaskawa Motoman robots |

| Universal Robots | Odense, Denmark | Collaborative robots for SMEs and flexible deployments | Universal Robots cobots |

About the Author

Dr. Emily Watson

AI Platforms, Hardware & Security Analyst

Dr. Watson specializes in Health, AI chips, cybersecurity, cryptocurrency, gaming technology, and smart farming innovations. Technical expert in emerging tech sectors.

Frequently Asked Questions

How do industrial robots improve manufacturing efficiency in measurable terms?

Robots boost throughput and quality by executing repetitive, high-precision tasks consistently, which raises OEE and reduces scrap and rework. IFR reports the global installed base numbers in the millions, indicating scale effects across industries such as automotive and electronics. McKinsey Global Institute estimates automation can add roughly one percentage point to annual productivity growth, with robotics central to material handling, welding, and inspection. When combined with machine vision and offline programming, robots compress changeover time and stabilize takt, delivering sustained yield and uptime gains.

Who are the main industrial robotics vendors and how do they differ?

Core manufacturers include ABB, FANUC, KUKA, Yaskawa, and Universal Robots, each with distinct strengths. ABB offers broad portfolios with RobotStudio for offline programming, while FANUC emphasizes reliability at scale in high-speed applications. KUKA focuses on flexible, integrated cells, and Yaskawa leverages deep motion-control expertise. Universal Robots catalyzed collaborative robots for SMEs and high-mix lines. Surrounding platforms from Siemens, Rockwell Automation, and Nvidia provide control integration, simulation, and AI to connect robots with wider production systems.

What are best practices for deploying robots with strong ROI?

Successful programs standardize robot cell designs, use offline programming to validate paths, and simulate flow with digital twins before physical build-out. Integrating controllers with PLCs, vision, and MES through deterministic interfaces, then instrumenting for telemetry, enables continuous improvement. Governance matters: apply ISO 10218/TS 15066 for safety, and ISA/IEC 62443 for cybersecurity. Many manufacturers incrementally scale from a flagship line to networked cells, reusing libraries and fixtures to compress commissioning and reduce engineering hours per deployment.

How do safety and cybersecurity factor into robotic systems?

Safety-by-design is fundamental. ISO 10218 sets requirements for robot systems; ISO/TS 15066 details collaborative operations, including force and speed limits. These inform risk assessments, guarding, and safety-rated monitored stops. As robots connect to networks, ISA/IEC 62443 guides defense-in-depth: segmentation, hardened controllers, authenticated updates, and least-privilege access. Following vendor hardening guides from Siemens and Rockwell Automation and auditing remote-access paths reduces attack surface while maintaining uptime for support and updates.

What trends will shape the next generation of industrial robotics?

AI-native cells and richer digital twins are redefining capabilities. Deep-learning vision improves random bin picking and defect detection, while GPU-accelerated inference reduces cycle time on high-mix lines. Simulation platforms such as Nvidia Omniverse and Isaac Sim, often paired with Siemens software, let engineers optimize layouts and robot paths virtually before deployment. Vendors are also expanding collaborative and mobile manipulation, blending safety, perception, and flexibility to adapt to demand swings without massive retooling.